With the in-depth advancing of intelligent manufacturing and industrial interconnection, the prominent phenomena of industrial field communication are: large number of communication equipment, complex environment, difficulty in wiring,not enough data volume, strong reliability, high efficiency, equipment dynamics (mobile), etc.

Widely used in intelligent garage, intelligent storage, intelligent sorting, intelligent production line and other scenarios.Industrial communication, on the market at present mostly adopts the following three ways: Ⅰ. Wireless AP & Wireless Client Communication.Ⅱ.Leaky Wave Communication. Ⅲ. Infrared Communication.For more than ten years' experience, Kunshan Wondertek Technology Co., Ltd. has designed a set of communication scheme -- CRC2ETHTM, which meets the characteristics of current industrial

communication, based on the basic technical theory research of power carrier technology and the accumulation of a large number of practical application scenarios.The following is a comparative analysis of these three industrial communication methods:

Ⅰ. Wireless AP + Wireless Client communication: first of all, It is the advantage of industrial communication mode that it can access a certain amount of terminals, to meet the needs of multiple communication equipment industry environment;Secondly, combination is convenient and management is simple. However, its disadvantages are also relatively obvious, such as:

♦ A. The price of wireless AP suitable for industrial field in the market is often high, which greatly increases the cost of enterprise intelligent manufacturing upgrade;

♦B. Wireless AP cannot be used alone like wireless routers, but needs to be used together with other devices, such as switches and AC;

♦C. Wireless network takes air as the medium, and it is easy to get disconnected or packet loss when encountering obstacles in the transmission process. However, in industrial sites, there are often more metal and more barriers, which greatly affects the effect of wireless communication and is not conducive to the stable operation of the system;

♦D. difficulty in wireless AP wiring;

♦E. Channel interference problem exists in wireless AP;

♦F. Disconnection occurs when the wireless client switches between different APs;

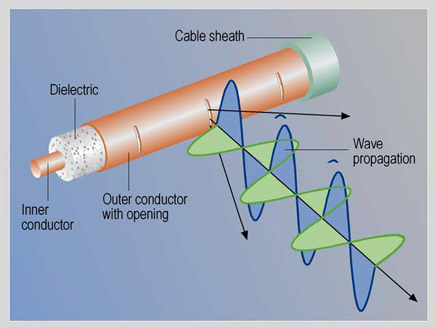

Ⅱ. leaky wave communication:It is suitable for wireless coverage in a complicated environment, no wear, make the maintenance quantity is reduced greatly.Its disadvantages include:

♦A. special leaky-wave cables need to be laid, and the installation accuracy, equipment cost and construction cost are very high;

♦B. Leaky-wave cable shall be laid in sections, and there are problems such as roaming disconnection;

♦C. Vulnerable to other same-frequency interference in the environment, which affects communication;

Ⅲ. infrared communication: just as its name implies is to use infrared, point-to-point high speed data connection, due to the correlation form loop is needed to transmit information, with a strong security.Its limitations are as follows:

♦A. High installation accuracy and equipment cost;

♦B. Directional communication (no turning), short distance;

♦C. Because of the light wave transmission, communication will be interrupted in case of obstacles;

The new industrial communication scheme CRC2ETHTM independently developed by Kunshan Wondertek Technology Co., Ltd.is designed to realize high-speed Ethernet bus Communication by CRC2ETHTM host, CRC2ETHTM client and a separate 3-pole conductor bar. CRC2ETHTM can achieve TCP/IP transmission bandwidth of up to 600Mbps or more with communication distance up to 800m, and overall network delay less than 20ms.It can realize high speed bus communication with communication nodes up to 32. The CRC2ETH device adopts OFDM technology which is based on the HomePlug & G.HN underlying protocol standard, and has MIMO transmission characteristics.The following is an example of a warehouse sorting system:

A. Project Introduction

Cross belt sorting is a commonly used sorting method at present. It is composed of a group of AGV and a closed conveying and sorting system. It is widely used in the logistics industry.

B. Communication System

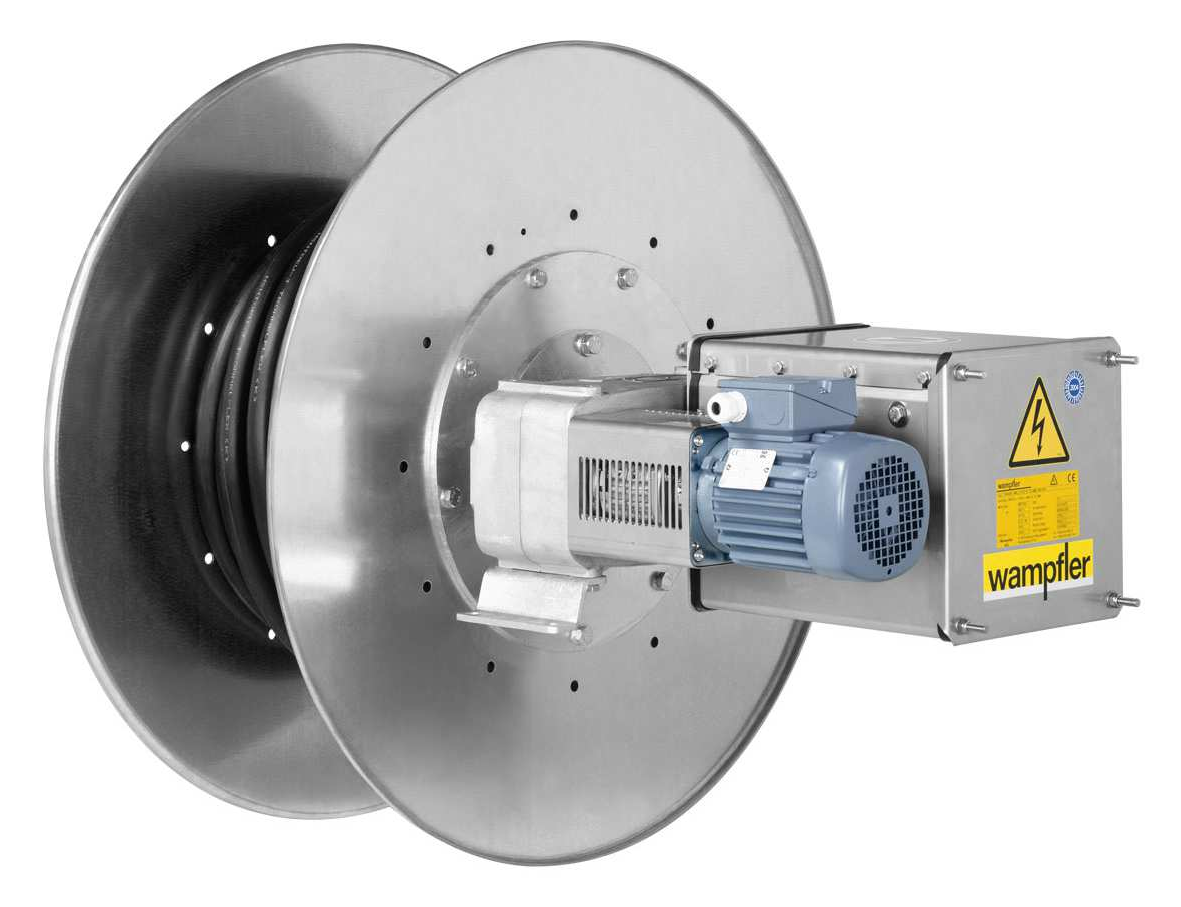

This project adopts the CRC2ETHTM high-speed bus communication system of Kunshan Wondertek Technology Co., LTD.The sorting machine's annular track is about 300 meters in length. After installing the power supply conductor rail, a 3-pole conductor rail of DGH89-01 3P30A is arranged separately for communication. There are 12 groups of trolleys running on the track, and each group of trolleys assembles a CRC2ETHTM client WD-1001M-DIN-S (HD01). The three terminals of the carrier signal interface of CRC2ETHTM client are connected with three carbon brushes, which communicate with the conductor rail DGH89-01.The Ethernet port of CRC2ETHTM client and the Ethernet port of the terminal control device are connected by cable line to build network communication.Install another CRC2ETHTM host in the control cabinet.

WD-1001M-DIN-M(HD01), the three terminals of the carrier signal interface of the CRC2ETHTM host are connected to the cable (the cable is connected to the conductor rail of the extension of CRC2ETHTM);The Ethernet port is connected to the host computer or other network control device to realize 1:12 high - speed bus communication.There is no harmonic interference on conductor rail, and the CRC2ETHTMdevice adopts OFDM technology, is based on HomePlug & G.hn standard, and has MIMO transmission characteristics, which ensures the stability of the system.

C. Results of Project Operation

This system using high speed bus communication system has been put into use in this warehouse for nearly 1 year. At present, the operation condition is stable, which has been unanimously affirmed by users and industry experts.

During the commissioning and operation of the whole project, the technical engineers of Kunshan Wondertek Technology Co.,Ltd. arrived at the site many times for guidance, help to analyze and solve unexpected problems on site.

Learn more

Learn more